McHenry Brass in Action

We will take you on a pictorial tour of the production of our parts so you can see how we make our products.

We start with the certified ingot of the specific material we are casting.

Based on the specifications of the part, we then select the proper pattern. Our staff of experienced molders put up the mold for that piece. This particular piece is being sand-cast, but we can also do centrifugal and continuous cast products.

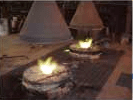

The raw ingot is then placed into the crucibles, which are lowered into the furnaces until the metal becomes molten. It is then poured into the mold.

The piece has now been cast. It will solidify and be allowed to cool until it can be taken into the machine shop.

The material is then put on the machine and is machined per the customer specifications or blueprint.

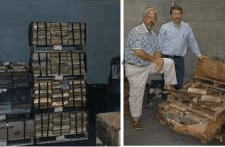

We also have a large selection of C932 and C954 tube and flat stock that can be used for a variety of parts, so you don’t have to wait for them to be cast.

Here are some examples of what we can produce for you.

We can also produce and stock items if they are to be ordered repeatedly.

The parts are now ready to be shipped to the customer. We routinely ship via UPS, Next Day, Common Carrier, and our own trucks to assure the fastest delivery possible.

Here are some examples of what we can produce for you.

We can also produce and stock items if they are to be ordered repeatedly.

The parts are now ready to be shipped to the customer. We routinely ship via UPS, Next Day, Common Carrier, and our own trucks to assure the fastest delivery possible.